Manufacturing in the Twin Cities region has long been a backbone of the local economy, driving innovation and providing thousands of jobs. Behind the scenes, a critical but sometimes overlooked component of this success is the network of suppliers that provide essential materials, tools, and components. Many manufacturers rely on Industrial Hardware Suppliers Twin Cities to source the high-quality products necessary for efficient production, timely maintenance, and ongoing growth. For anyone searching for reliable partnerships to fuel manufacturing operations, this phrase often becomes a key search term online.

Supplying Quality and Consistency

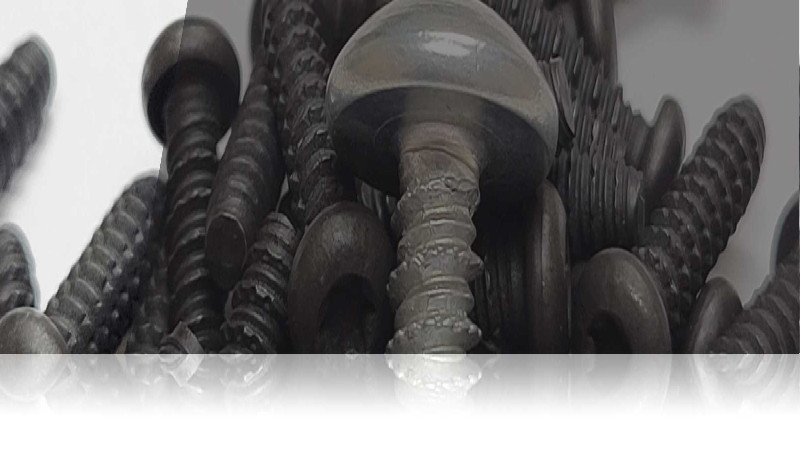

Local manufacturers are only as strong as their supply chains. Industrial hardware suppliers in the Twin Cities play a crucial role by offering a wide selection of fasteners, fittings, tools, and specialty components. Their ability to source and deliver products that meet strict industry standards ensures that production lines operate with minimal disruption.

Some of the key ways these suppliers support manufacturing include:

- Consistent inventory availability: Maintaining large, diverse stocks of hardware allows manufacturers to quickly find the parts they need, reducing costly downtime.

- Quality assurance: Suppliers often work closely with manufacturers to ensure every component meets exact specifications, eliminating the risks associated with subpar materials.

- Product expertise: Knowledgeable staff can recommend the right products for specific applications, helping manufacturers optimize their processes.

Fostering Efficiency and Innovation

Efficiency is vital in manufacturing, and dependable suppliers enable local businesses to stay competitive. By providing just-in-time delivery and flexible order quantities, industrial hardware suppliers allow manufacturers to streamline their inventory management. This reduces overhead costs and allows for more agile responses to changing market demands.

Additionally, suppliers often introduce manufacturers to new products or innovative solutions. Access to the latest advancements in fastener technology, corrosion-resistant materials, or assembly tools can lead to process improvements and cost savings. Suppliers frequently offer technical support and training, empowering manufacturers to adopt new technologies with confidence.

Strengthening Local Partnerships

The proximity of industrial hardware suppliers within the Twin Cities offers several advantages. Local suppliers understand the unique challenges and requirements of manufacturers in the area, from climate considerations to industry-specific regulations. This localized knowledge allows for more personalized service, faster response times, and stronger business relationships.

Manufacturers also benefit from the community-oriented approach of local suppliers, who are invested in the region’s economic success. Reliable suppliers become trusted partners, contributing not only to the operational success of individual businesses but also to the broader health of the local manufacturing sector.

Supporting Growth and Adaptation

As industries evolve, the demands placed on manufacturers and their suppliers increase. Industrial hardware suppliers in the Twin Cities are instrumental in helping manufacturers adapt to new technologies, sustainability initiatives, and changes in production volume. Their flexibility and commitment to continuous improvement make them invaluable allies as local businesses strive to grow and remain competitive in a global market.

In summary, the relationship between Twin Cities manufacturers and their industrial hardware suppliers is a cornerstone of regional economic vitality. By providing quality products, technical expertise, and responsive service, these suppliers help local manufacturers thrive in an ever-changing industry landscape. Choosing the right supplier is not just about sourcing hardware—it’s about building a partnership that supports long-term manufacturing success in the Twin Cities.